|

|

Hilhouse's New Dockyard, Thomas L Rowbotham (1826) (Bristol's Museums, Galleries and Archives).

Most of the ships built at Bristol were for trading purposes but some warships were built here including the 12 ships built for the Admiralty by James Martin Hilhouse between 1778 and 1786.

This work helped lay the foundations for Bristol's longest running shipbuilding firm, Charles Hill & Sons Ltd, which launched its last ship on 4 January 1977.

A Bristol Fighter somewhere on the Western Front, 1917. Picture from the Aviation Archive website.

A more significant contribution was made to the military by the aircraft industry. The Bristol Aeroplane Company (BAC) at Filton, which was established in 1910, underwent major expansion during World War One when the War Office re-equipped its reconnaissance squadrons with the famous Bristol 'Fighter', a two-bay bi-plane. By 1918 BAC had built over 4,000 aeroplanes for military use and there were more than 3,000 people on the company payroll.

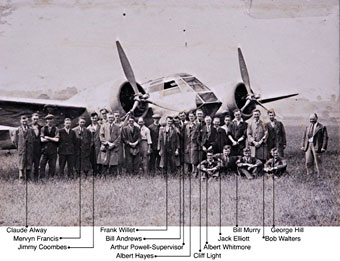

The first Blenheim to be built, along with some of the team that built her. Picture from the Aviation Archive website.

In the Second World War, BAC's Blenheim, which had been adopted by

the RAF as its standard light bomber in 1937, won more VCs than any

other aeroplane. Over 1,000 Blenheims had been built by the time

the war broke out in September 1939. In 1942 there were over 52,000

BAC personnel, some working at 'shadow-factories' and dispersal sites

in addition to Filton. From the following year many were

redeployed to other wartime priorities, including building tanks.

By the end of the war the company employed about 25,000 people.

BAC facilities covered with camouflage paint at start of World War

Two (Airbus).

A Parnall Turret, made by the Yate based company, on shown in London's 'Wings for Victory Week' 8th - 13th March, 1943. Picture from the Aviation Archive website.

Another important local aircraft manufacturer, Parnall, also contributed to the war effort. The company was awarded a contract from the Admiralty to produce a variety of aircraft during World War One and during the Second World War specialised in the manufacture of aircraft components.

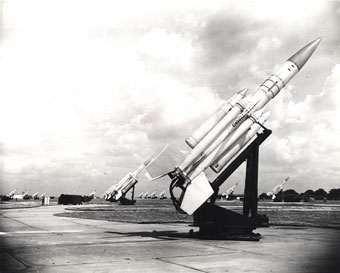

Bristol-Ferranti Bloodhound I missiles on their launchers at Royal Air Force Station, Watton. Picture from the Aviation Archive website.

BAC's immediate post-war work included the setting up of a guided

missile project which led to the manufacture of the Bristol-Ferranti

surface to air missile (SAM), the Bloodhound. The Bloodhound was

the RAF's only long range/heavy SAM and was in service until 1989.

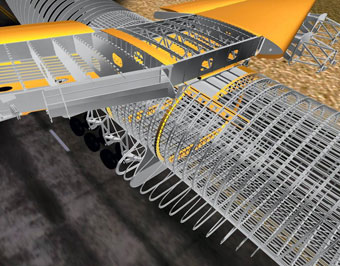

Computer-generated image of the structure of the

Airbus A400M military transporter (Airbus).

Today Airbus at Filton is recognised as a centre of excellence

for the design of wings, design integration of the landing gear

and the manufacture and sub-assembly of wing components. Around

6,000 people work in the design offices, manufacturing areas

and in other departments like customer support, finance and procurement.

Since the mid 1990s over £700 million has been invested

in new machinery, technologies equipment and facilities for Airbus

at the Filton site, including most recently in a new operation

for the assembly and equipping of the composite-metallic hybrid

wings for the new A400M military transporter.

Rolls-Royce's current

Bristol operations include the company's Defence Aerospace division

and the Marine division. Current programmes include the Type

45 Destroyer for the Royal Navy and the multi mission destroyer

DD(X) for the US Navy.

|

|

|

|